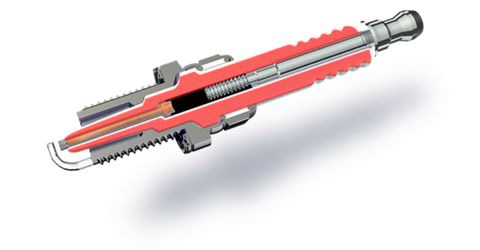

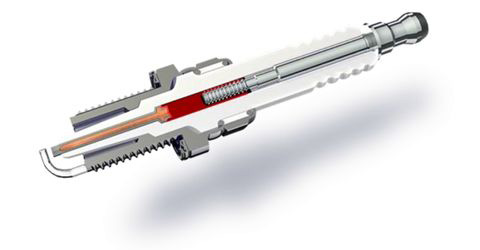

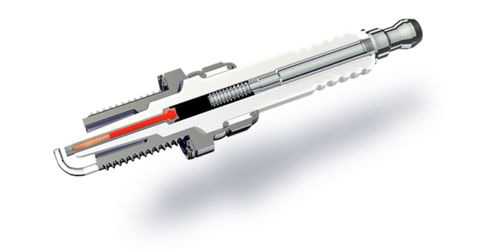

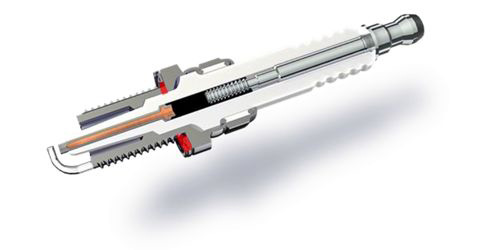

Parts of a spark plug: The vital components

What do spark plugs do

Spark plugs are necessary for any petrol-fuelled ignition combustion engine. They work by igniting the air-fuel mixture in an engine that creates combustion which pushes the pistons down, ultimately providing power to a car.

Just like the ones used in the 1930s, a spark plug is still screwed in and consists basically of a thread, a metal sleeve, electrodes and a ceramic insulator.

Cars, nevertheless, have changed significantly over the decades in terms of appearance, power and safety. Spark plug innovation, however, has kept pace, meaning that the ones produced today are able to withstand much higher voltages, pressures and temperatures, as well as being able to dissipate more heat.

The 8 parts of a spark plug

1. Terminal

The connection terminal is usually an SAE ‘barrel’ shaped connection, a 4 mm thread or a ’cup design’. The high tension ignition lead or a pencil coil is plugged onto the terminal. This connection allows the high voltage to be transferred to the firing end of the spark plug.

2. Ceramic insulator

Most spark plugs used today feature a single-ceramic insulator made from aluminium oxide, with other types of ceramic materials like porcelain used in the past. This provides many benefits, including thermal conductivity and superior insulation. Resistance to overheating, thermal and mechanical shock are other stand-out features. It also helps to prevent overheating and provides exceptional resistance against mechanical and thermal shock.

3. Resistor

In order to ensure electromagnetic compatibility (EMC) and thus the fault-free operation of the onboard electronics, a ceramic resistor is used inside the spark plug as an interference suppression device. It is constructed by a fusion of carbon and glass compounds which form a solid component within the spark plug. It also prevents interference with electronic components that are not located on the vehicle e.g. domestic TV and radios.

In most vehicles, a resistor spark plug is required for optimum operation because radio frequency interference (RFI) can cause the other electrical components in the car to break down prematurely.

Use of non-resistor spark plugs in vehicles that require them can result in rough idling, abnormal combustion and misfires. Since resistor spark plugs cause a reduction in spark energy, non-resistor ones provide a stronger spark, which is why these types are most commonly used in racing.

4. Centre electrode

The centre electrode can be made from nickel, copper, chromium and precious metals such as iridium and platinum.

It is connected to the terminal by an internal copper wire, which carries high electrical voltage through the spark plug to the tip of the centre electrode, where it then jumps the small gap to the ground (side) electrode, creating a spark.

Centre electrodes can vary in terms of size and shape. Standard plugs, for example, generally have a 2.6mm centre electrode. NGK SPARK PLUG’s precious metal plugs such as ‘Laser Iridium’ and ‘Iridium IX’, however, have a centre electrode of 0.6mm, made from iridium.

With a smaller electrode, less voltage is required to jump the electrode gap, which leads to fewer misfires and improves ignitability. NGK SPARK PLUG’s special firing end design ‘v-grooved centre electrode plug’, moreover, features a v-groove cut into the centre electrode, which is situated parallel to the ground electrode. This results in improved ignitability and reduced quenching.

5. Ground (Side) electrode

Once the spark jumps the gap from the centre electrode to the ground electrode, a spark is created which ignites the fuel in the combustion chamber.

The ground electrode can come in a variety of shapes and sizes. Some (multi-ground spark plugs) can even feature two, three and four ground electrodes. These, however, do not create more sparks than a spark plug with one ground electrode.

For both single and multi-ground electrode spark plugs, only one spark is created at a time. Standard spark plugs generally feature a ground electrode made of nickel, while premium plugs feature precious metals such as iridium and platinum which, due to their hardness, are much more durable than standard metal plugs.

6. Gasket

The gasket ring prevents any possibility of combustion gas leaking past the spark plug due to the extremely high combustion pressures. In doing this, it prevents any cylinder pressure losses.

Another important function is that it provides good conduction of head to the cylinder head and evens out the different expansion properties of the cylinder head and spark plug housing.

7. Metal Shell

This is the steel shell which a socket wrench fits around in order to loosen and tighten a spark plug. A plug’s hex head can come in a variety of sizes, which include 13mm, 14mm, 16mm, 18mm, 19mm, 21mm, 22mm, 24mm, 25mm and Bi-Hex 14.0mm.

8. Ribs or Corrugation or Leakage Barriers

Located above the terminal, the ribs help to protect against spark flashover.

As has been demonstrated, the spark plug – despite its small stature - is a highly complex piece of technology.

The spark plug’s parts consist of a multitude of different components that work in unison to provide a petrol-fuelled engine with the perfect ignition spark.

At NGK SPARK PLUG, a strong emphasis is placed on achieving consistently high levels of customer satisfaction – one of the company’s three main goals. Indeed, Aftermarket customer satisfaction is particularly high for its products and services, which is demonstrated by the company’s most recent Net Promoter Score (NPS) of 67, having increased by two points since its last edition. The NPS measures the willingness of customers to recommend a company, with NGK SPARK PLUG well above the average benchmark value of 41.

To learn more about the workings of this fascinating ignition catalyst, log on to https://www.tekniwiki.com.