Lights, camera, action! New device tests and films the ignition behaviour of spark plugs under real-life, high pressure conditions

Necessity is the mother of invention

“Our technical experts faced a challenge,” says Kai Wilschrei, Manager Technical Services Aftermarket EMEA

at NGK SPARK PLUG EUROPE’s headquarters in Ratingen. “The spark plug testers commercially available to

date couldn’t generate the same extreme pressure that downsized turbo engines place on today's spark plugs.

So we had to come up with a solution.”

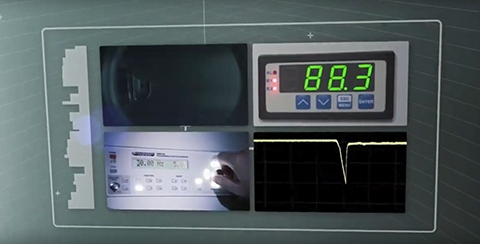

This high-tech spark plug tester display shows a pressure of 88.3 bar.

That's why three departments joined forces. Together, the Quality Assurance, Technical Centre

and Technical Service teams came up with an innovation which helps to keep NGK SPARK PLUG’s product

quality at the highest level. After two years of brainstorming and prototyping, the company’s engineers

developed and built their own, unique device to test the high-performance spark plugs under real conditions.

“Instead of the usual 10 bar, this one-off unit can now increase the pressure up to 100 bar,” explains Kai.

But the high-tech device doesn’t stop there. “The pressure chamber, which we designed ourselves, has sight

glasses which also resist pressure up to 100 bar. This makes it possible to film and transmit the spark and

ignition performance of the plugs with the help of the installed high-speed cameras – and that’s in real time, taking 1-150 frames per second.”

Informing future engine development

The test results can also be saved and sent to the relevant department by using high quality software.

The Technical Service team mainly uses the new tester to investigate performance issues and to carry out

product comparisons. The company’s Quality Assurance team for original equipment (OE) also extract important

information from the tests to advance the development of new plugs. As a result, NGK SPARK PLUG

is fully equipped to meet the demands of future engine downsizing.

Why turbo engine downsizing?

“The trend towards engine downsizing comes from car manufacturers’ attempts to design

more efficient vehicles that produce less carbon emissions,” continues the Manager Technical Service.

“In order to reach that goal, manufacturers increasingly tend to construct small engines with reduced

engine displacement and a lower number of cylinders,” says Kai. Recent technologies, like an added

forced aspiration device (such as a turbo or supercharger) or direct injection technology, enable downsized

engines to perform like a much larger one. In addition, a smaller engine is often lighter, which reduces

the car’s overall weight and improves its agility. On top of that, fewer cylinders means less friction in the

engine, increasing its efficiency. “However, of course, that also increases the pressure inside the

cylinders – and on the spark plugs – to new levels,” explains Kai.

To sum it up, Kai says: “We don’t expect this trend to end. It’s more of a continual evolution.

But with our new invention, NGK SPARK PLUG is well prepared for future developments.”

The innovative device resides in the Technical Centre at NGK SPARK PLUG EUROPE’s headquarters in Ratingen.

Niterra Blogs

Niterra Blogs